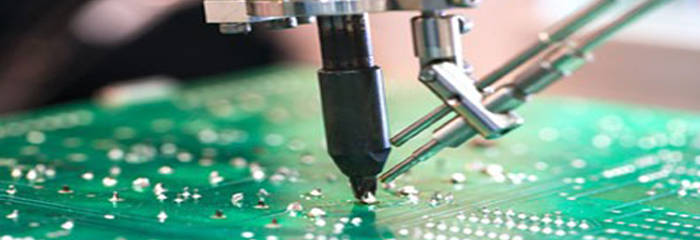

The main effect of the PCB entry sheets

As the auxiliary material for PCB drilling, the cover has five main effects:

1.protection board (protection of copper clad copper plate surface, or copper substrate conductive layer), to prevent the pressure foot pressure plate;

2. fixed drill, Reduce the drill bit when the drift amplitude, offset, so that the drill bit can be accurately positioned; to improve the hole accuracy, to prevent the broken drill;

3. to prevent the hole on the substrate burns;

4. help drill bit heat, reduce the bit temperature; Groove; to prevent greasy dirt; to reduce the wear and drill bit drills.

5.The performance requirements of the drilling entry boards are: soft enough; thickness tolerance is small; flat and not easy to deformation; high temperature; low moisture absorption; surface no impurities, foreign matter, obvious defects and so on.

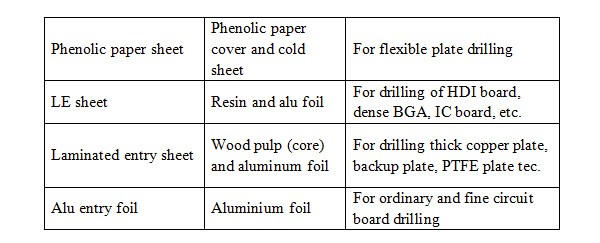

Drilling entry material variety

According to the different materials, the market is usually divided into four categories: phenolic paper sheet(including phenolic paper cover and cold sheet), coated resin aluminum sheet (also known as lubrication aluminium sheet), aluminium entry sheet (Ie aluminium entry foil), epoxy glass cloth sheet. Phenolic paper sheet industry less amount, and cold sheet(commonly known as phenolic paper sheet) is mainly used for flexible plate drilling; coated resin aluminum sheet for HDI board, dense BGA, IC board, etc. Micro-hole drilling and flexible plate drilling, made of resin and aluminum foil; aluminum entry sheet or aluminum entry foil, for ordinary and fine circuit board drilling, made of alloy aluminum foil; epoxy glass cloth cover, by the ring Oxygen resin and fiberglass cloth composition, the current market use very little. In addition, there have been a composite aluminum sheet, from wood pulp (core) and aluminum foil composition, fairly rare, has been out of the market.

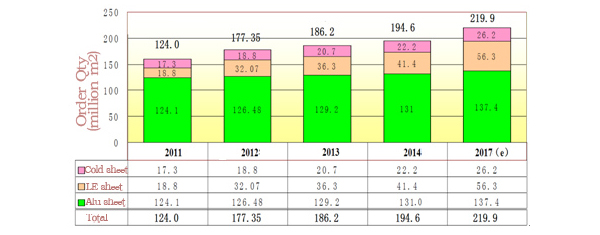

With the development of PCB technology, PCB drilling holes are getting smaller and smaller, more and more holes, drilling technology requirements are getting higher and higher, entry sheet on the drilling quality of the impact is more important. Some high-end or high-tech requirements of the PCB boards, generally use some of the high-end entry sheet. PCB in the market with the entry sheet of the product structure, with the development of PCB technology, PCB product structure continues to upgrade, and PCB drilling technology upgrade. The selection of drilling materials are in the high block plate, such as lubricating aluminum sheet, cold sheet, phenolic paper pad, melamine wood plate. In particular, high-grade LE sheet, PCB drilling special entry material, HDI (including IC carrier board) with cover, flexible PCB drilling with cold plate, etc. become the market faster varieties.

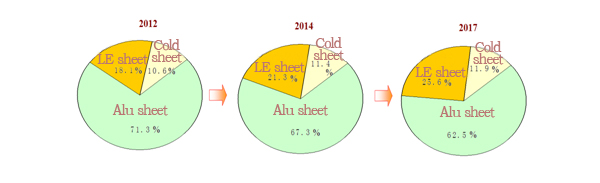

For rigid high-tech, microporous PCB and FPC drilling processing of lubrication aluminum sheet demand in recent years will gradually increase. According to statistics, the market demand for lubrication aluminum sheets in 2012 accounted for 18.1% of the global volume of the cover, and its market share has increased to 21.3% by 2014, and the proportion is expected to expand to 25.6% in 2017 (see Figure 3). The demand for cold sheet for the drilling of the flexible plate will also show a certain trend. It accounted for 10.6% of the global total sheet cover in 2012 and 11.4% in 2014.